Drilling for Crude Oil

Once the well site has been prepared and the rig system set up to meet all safety and environmental regulations drilling can begin. Drilling the well involves several stages starting with a large diameter hole with the hole becoming successively smaller as the well is deepened.

The animation below shows the key stages in the drilling of a typical onshore vertical well.

Animation Summary:

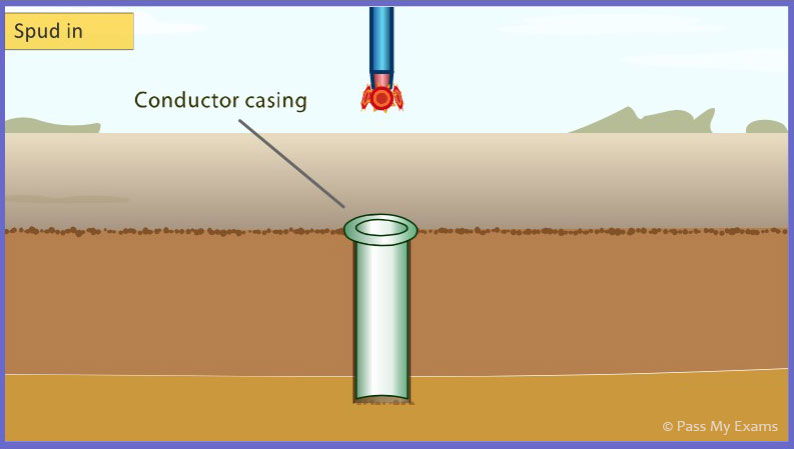

A large diameter hole is drilled using a large diameter drill bit. Drilling is conducted by heavy duty industrial strength drill bits. The drill bits come in different sizes according to the diameter of the hole being drilled. Conductor casing is then cemented in place to stabilize the ground around the drilling rig and isolate the well from ground water sources.

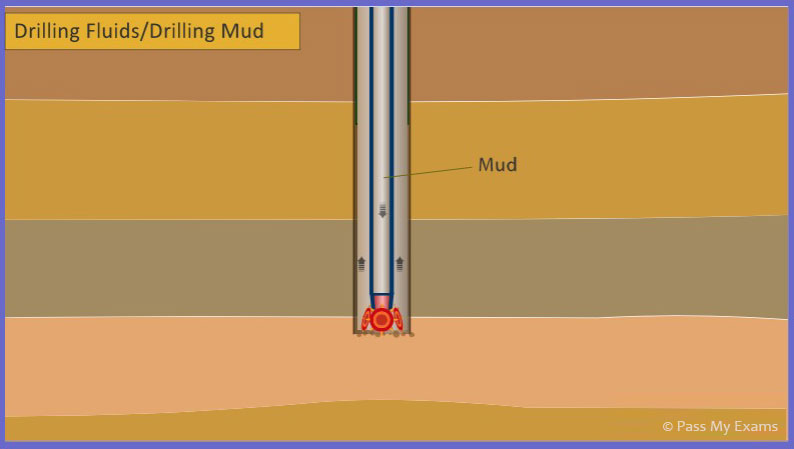

The drill bit is then run through the inside of the conductor casing via the drill string to continue drilling. Drilling fluids/drilling muds are pumped down the drill string, out through the jets in the drill bit, and travel up back through the space between the drill bit and the walls of the hole. The drilling mud carries away all the rock cuttings, keeps the drill bit cool and lubricated, balances the well bore pressure and prevents formation fluids from flowing into the well bore.

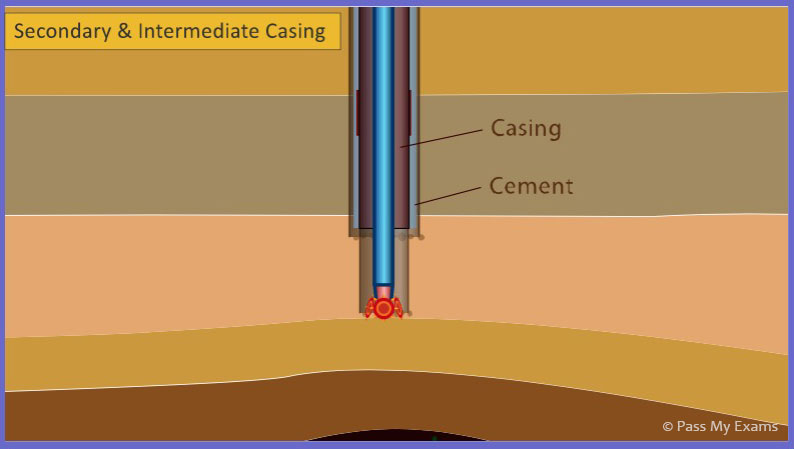

On reaching the required depth, the drill string is pulled out of the hole. Surface casing made up of lengths of steel pipe screwed together is then inserted into the hole. To permanently secure the casing in place, cement followed by mud is pumped inside the casing. Mud is separated from the cement by a cementing plug. The plug is pushed by the mud to ensure the cement travels outside of the casing and up through the space between the casing and the well wall. Depending on the required depth of the well, secondary or intermediate casing may need to be installed, in which case the method is repeated.

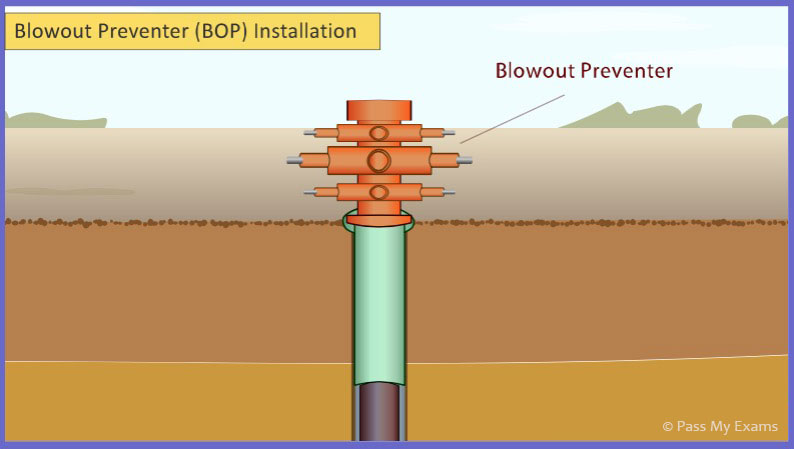

On completion of the surface casing cementing, a blowout preventer is installed at the top of the well. The blowout preventer is a safety system consisting of hydraulically operated valves and pipe rams to protect the drilling rig and the environment from excessive pressures in the formation reaching the surface.

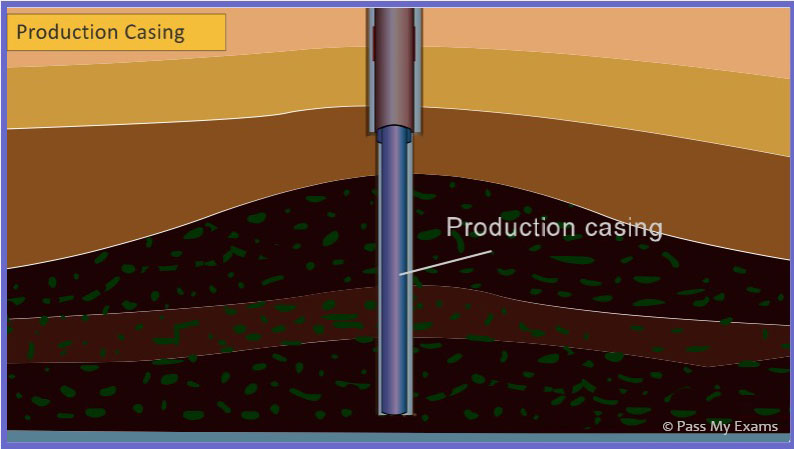

Drilling continues with the drill string (drill pipe and drill bit) operating through the blowout preventer. A smaller drill bit is fed down the secondary/intermediate casing and drills through the cement plug at the bottom continuing its journey till it reaches the oil/gas target zone. Production casings are inserted and cemented in place using the same method applied for the secondary casing. During the whole drilling process, samples of the drilling mud are examined by a process called logging. The purpose of this is to compile a comprehensive record of formation changes and provide guidance to the drilling team on drilling rates and correct drilling fluids to use.

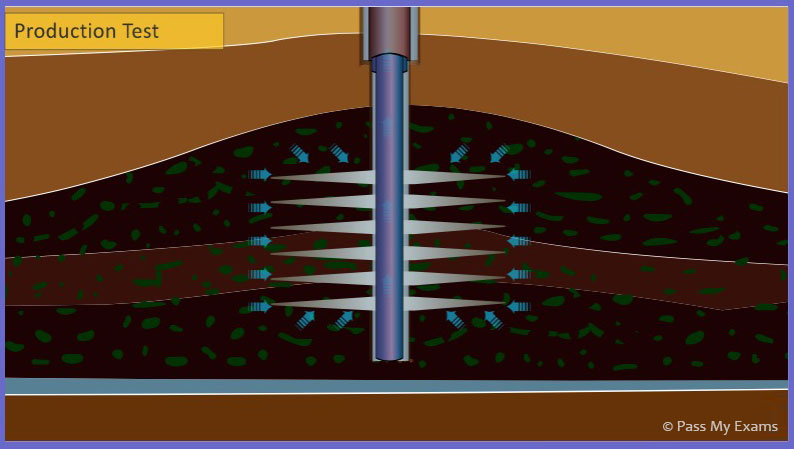

In order to test the production capability of the well, a flow test is undertaken. The production casing is perforated by firing a string of specially designed charges and the oil begins to flow. The flow of hydrocarbons results in the pressure in the reservoir to be reduced. The well is shut in after a period to allow for the pressure in the well to build up again after the initial flow. It is then reopened for a second or even a third measurement. Continuity of pressure during the test and the rate of pressure build up give an indication of the permeability and performance of the reservoir in full production mode. Gas released from the well during testing is burned off using a flare. If during test the flow is small or marginal and not deemed economical for further development it will be plugged and abandoned. This is done by plugging the piping in the various formations with cement.

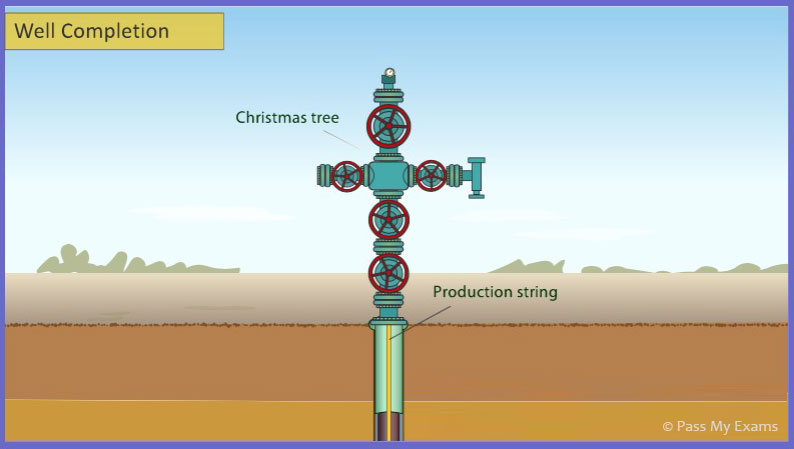

If the well is deemed to be commercial, a production string is installed. The production string consists of a tubing string with a packer near the bottom. The packer is positioned above the perforations to ensure all the hydrocarbon reach the surface through the production tubing. Before the drilling rig is dismantled a system of valves called a Christmas tree is installed at the wellhead in place of the blowout preventer, which can be connected to the production system at a future date. Further wells are drilled to determine the extent of the reservoir.